Aluminium Stamping Wireless Chargers

Aluminium is a great material to be used as a housing case for Wireless Chargers. It has decent looking & metalic feeling after finishing treated. Aluminium also very cost effective due to its reasonable budget. There are usually two type of technique making aluminium into our needed Wireless Charger housing case. One is by Stamping through a custom made Mold, the other is by CNC Metal Craft, using high tech CNC machine to achieve the shape we want. Mold Stampling make products via Aluminium Panel ( very thin panel, usually in mm ), while CNC Metal Craft the items though a solid Alumium Bar or Block. So the cost are very different, because of material cost & production effiency vary large.

Aluminium Stamping can be easy, because a custom made stamping mold is not expensive, ranging from 400 USD - 700 USD, depending on the wireless charger housing case size and design. TopWirelessCharger already have a few models for Aluminium Stamping Wireless Chargers, from our ready existing products, you may get some inspiration and design your own. We are ready here for your OEM ODM order, pls Talk With Us for more details. Pls always remember, if budget is not a problem, you can try CNC Metal Craft for a new Wireless Charger. It is higher cost, but the quality metalic feeling both in touching and weight will solidly deserve the investment.

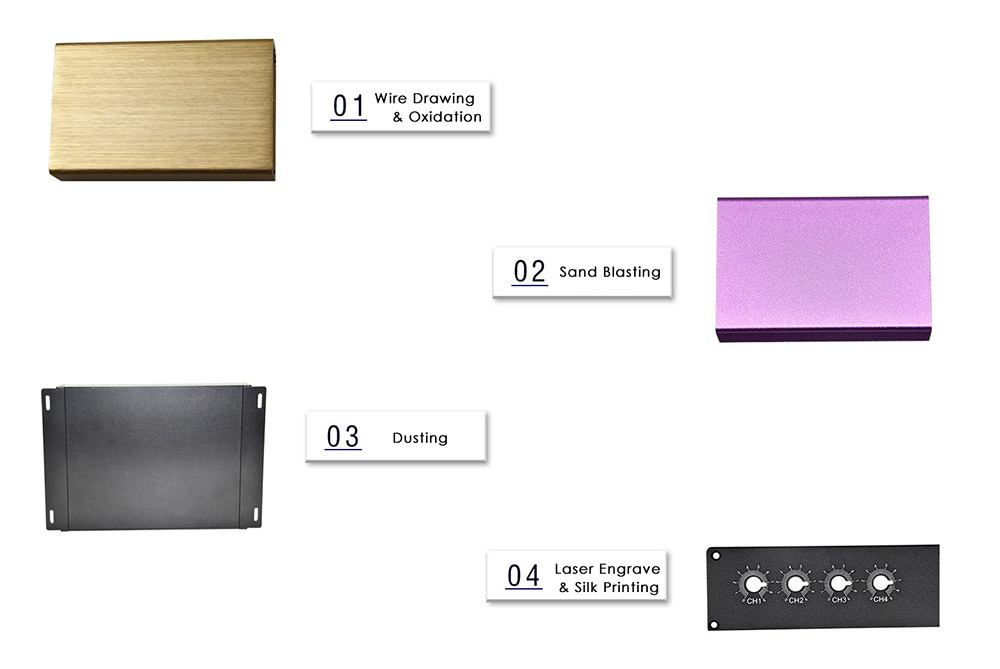

Different Type of Finishing For Aluminium Wireless Charger

There are several different type of Finishing Technique for Aluminium Wireless Charger housing case. Typically, it includes Wire Drawing & Oxidation, Sand Blast, Dusting, Laser Engrave & Silk Screen Printing. The most common used finishing is Wire Drawing & Oxidation, it give the housing case a high end metalic finishing while keep the surface smooth and comfortable. See below photos of different type of aluminim finishing. Talk with us for any more details of OEM / ODM Wireless Charger Project !